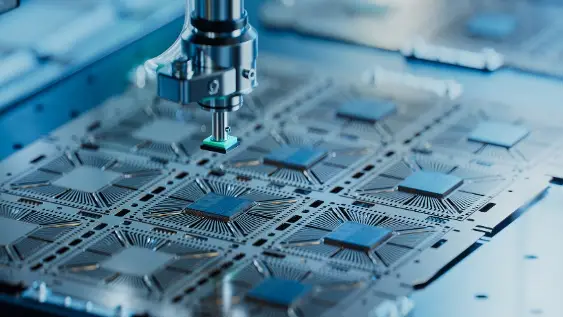

Our Services

Our unparalleled expertise enables us to navigate through well-known challenges, ensuring the development of architectures that sustain high performance with minimal latency, even when processing exceptionally large volumes of data. Our design capabilities span a broad spectrum of solutions and market needs.

Our Advantage

We prioritize excellence and innovation, embedding quality control and continuous monitoring at every stage of our comprehensive design services. Our approach is distinguished by direct client involvement, ensuring clarity, precision, and flexibility throughout the development process.

Our unique methodology offers you direct access to our development team, facilitating real-time adjustments and ensuring your vision is perfectly aligned with our execution. This collaboration extends beyond delivery, with our commitment to post-delivery support exemplifying our dedication to long-term partnerships.

Furthermore, our efficient supply chain management ensures the timely delivery of high-value, differentiated solutions, setting us apart in a competitive market. Hekratos is more than a service provider; we are your trusted partner in achieving success through technological innovation and operational excellence.

In summary, together with our Fabless services partner, we are delivering unparalleled quality, flexibility, and partnership, establishing a new standard in the microchip design industry.

A selection of projects done: (20+ in the last 3 years)

Multi-core DPU project, T12nm process, area 100mm2, spec in project, 2023 full mask tape out.

AI chip project, T12nm process, area 31mm2, RISC-V big-little structure, with MIPI/USB/ETH/SDIO interfaces, LP3/4 DDR, and the 2022/10 MPW tape out.

AI chip project, T12nm process, area 31mm2, RISC-V big-little structure, with MIPI/USB/ETH/SDIO interfaces, LP3/4 DDR, and the 2022/10 MPW tape out.

Multi-core DPU-2 project, T12nm process, area of 329mm2, 2022/6 3rd-party MPW, tape out .

Multi-core DPU-1 project, T12nm process, with an area of 329mm2 In October 2021, 100+wafers were mass-produced in tape out.

SSD project, T12nm process, onfi (Open Nand Flash Interface), ddr5/pcie5 area of 52m2, 2021/10 3rd-party MPW , mass-produced

Large-scale switch SoC, UMC28nm process, arc/ddr/pcie/SerDes, with an area of 100mm2, and tens of thousands of full mask tape outs have been mass-produced in June 2021.

And many more……

We have successfully addressed challenges that continue to perplex our rivals

Access to Multi-Project Wafer (MPW) services is notably scarce for certain technologies.

For large-scale chips, the cost of MPW services can equate to that of full mask production.

A significant number of customers lack a formal pathway for Tape-Out.

It's common to see a lack of mass production planning when large chips undergo Tape-Out for the initial time.

These challenges, which many in the industry face, have been effectively resolved by our team.

Contact us

Unlock limitless possibilities with Hekratos B.V., your trusted partner in custom microchip design solutions. Contact us today to transform your visions into cutting-edge realities.